Best Practices in Manufacturing

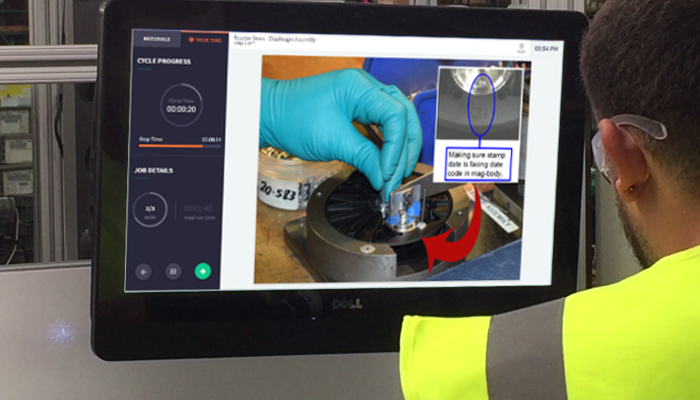

Training operators in manufacturing to operate machinery and equipment safely and effectively is crucial for any business. Visual learning, which relies on visual aids such as images, videos, diagrams, and infographics to convey information, can be one of the most effective ways to train operators. However, there are some things to keep in mind when using visual learning in operator training in manufacturing.

Why is Visual Learning Important in Manufacturing?

Visual learning can be particularly effective in manufacturing for several reasons:

- Safety: Visual aids can help demonstrate safety procedures, highlight potential hazards, and show how to operate machinery and equipment safely. This can reduce the risk of accidents and injuries on the job.

- Complex Processes: Visual aids can simplify complex processes, making them easier to understand and follow. This can help reduce errors and improve efficiency.

- Multilingual Teams: Visual aids can be a universal language that everyone can understand, regardless of their spoken language.

- Retention: People remember visual information more easily than written or spoken information. This means that operators are more likely to retain information presented through visual aids, which can improve their performance on the job.

- Engagement: Visual aids can make training more engaging and interesting for operators. This can help keep them focused and motivated, leading to better performance and job satisfaction.

What to Know When Using Visual Learning in Operator Training in Manufacturing

- Use high-quality visual aids: Low-quality visual aids can be distracting and confusing. Make sure your visuals are clear, concise, and easy to understand.

- Be consistent: Use consistent visuals throughout your training program to avoid confusion and help with retention.

- Provide context: Visual aids should be used to support and enhance the learning experience, not replace it. Make sure you provide enough context for operators to understand how the visuals relate to the task at hand.

What to Avoid When Using Visual Learning in Operator Training in Manufacturing

- Overloading: Avoid overloading operators with too much visual information at once. This can be overwhelming and counterproductive.

- Misrepresentation: Avoid misrepresenting information or oversimplifying complex procedures. This can lead to errors and safety hazards.

- Dependency: Avoid becoming too dependent on visual aids. Operators should still be able to perform tasks without relying solely on visual aids.

Visual learning can be a powerful tool in operator training in manufacturing. By incorporating visual aids into your training program while being mindful of what to avoid, you can improve safety, reduce errors, and enhance engagement and retention. So why not give it a try? Your team and your business will benefit from this effective and engaging approach to learning.

Jen Moore

I absolutely LOVE being outside. Being a soccer enthusiast and a dog mom, I spend much of my free time running with my pups or kicking a ball with my team.

3 min read

3 min read