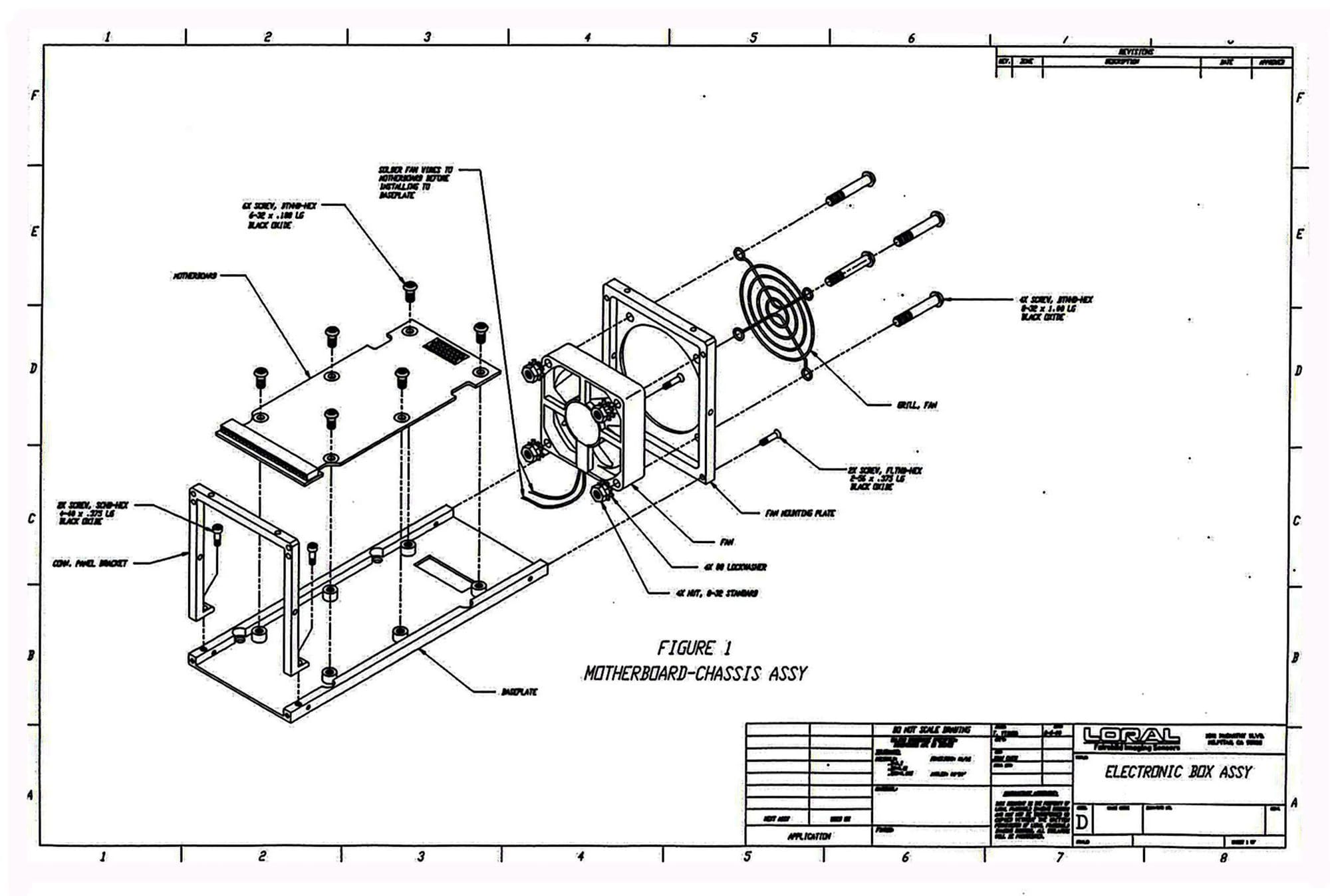

Clarity is paramount in the realm of assembly and fabrication. Consider an Operator on a bustling production floor, reviewing a complex engineering print, pressured by the urgency of getting the order completed in time. Amidst this chaos, the Operator searches for a lifeline - a Lead, a veteran Operator, anyone.

Good visuals bridge this divide.

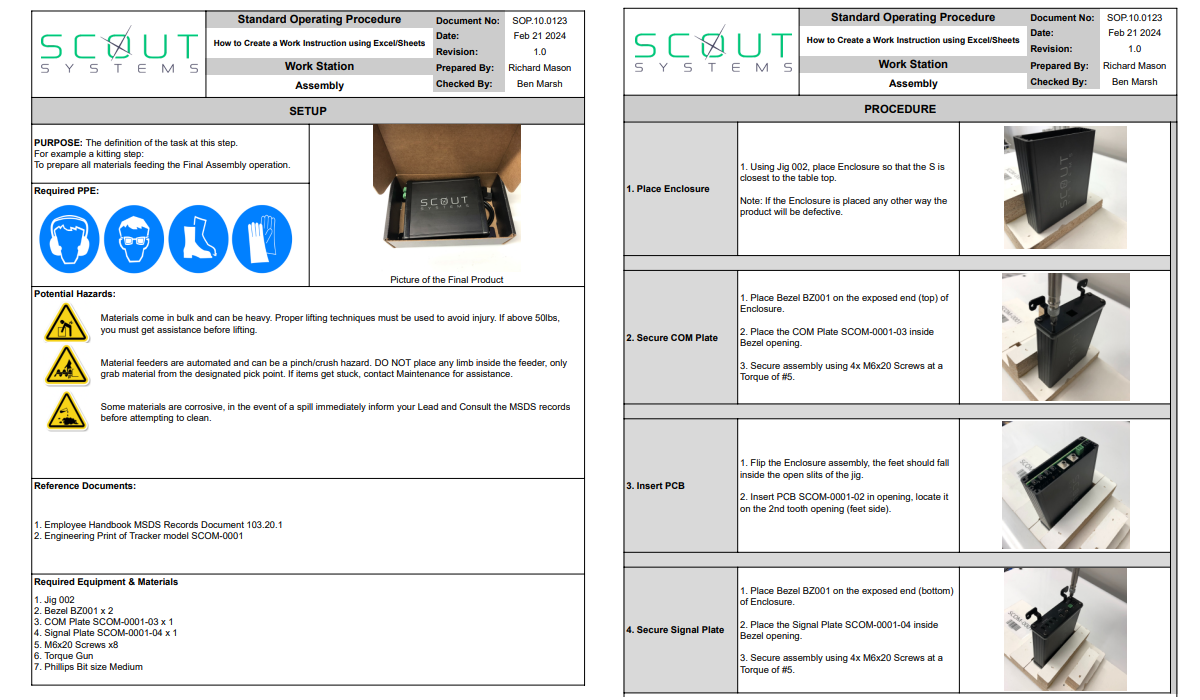

Visual work instructions break down complex procedures. They are indispensable tools that enable Operators to quickly decipher, interpret, and execute tasks with precision.

The Power of Visual Work Instructions

The term "visual" in this context signifies more than merely an image to observe; it encompasses the quality and utility that underscore its significance. When carefully chosen, images can serve as a 'universal language' comprehensible to operators of all skill levels. Factories that recognize and embrace the critical importance of effective visual work instructions cultivate an environment where ambiguity is significantly reduced.

Visuals Trigger Faster Comprehension

Visuals operate as conduits to clarity, offering an instantaneous bridge to understanding that surpasses textual descriptions.

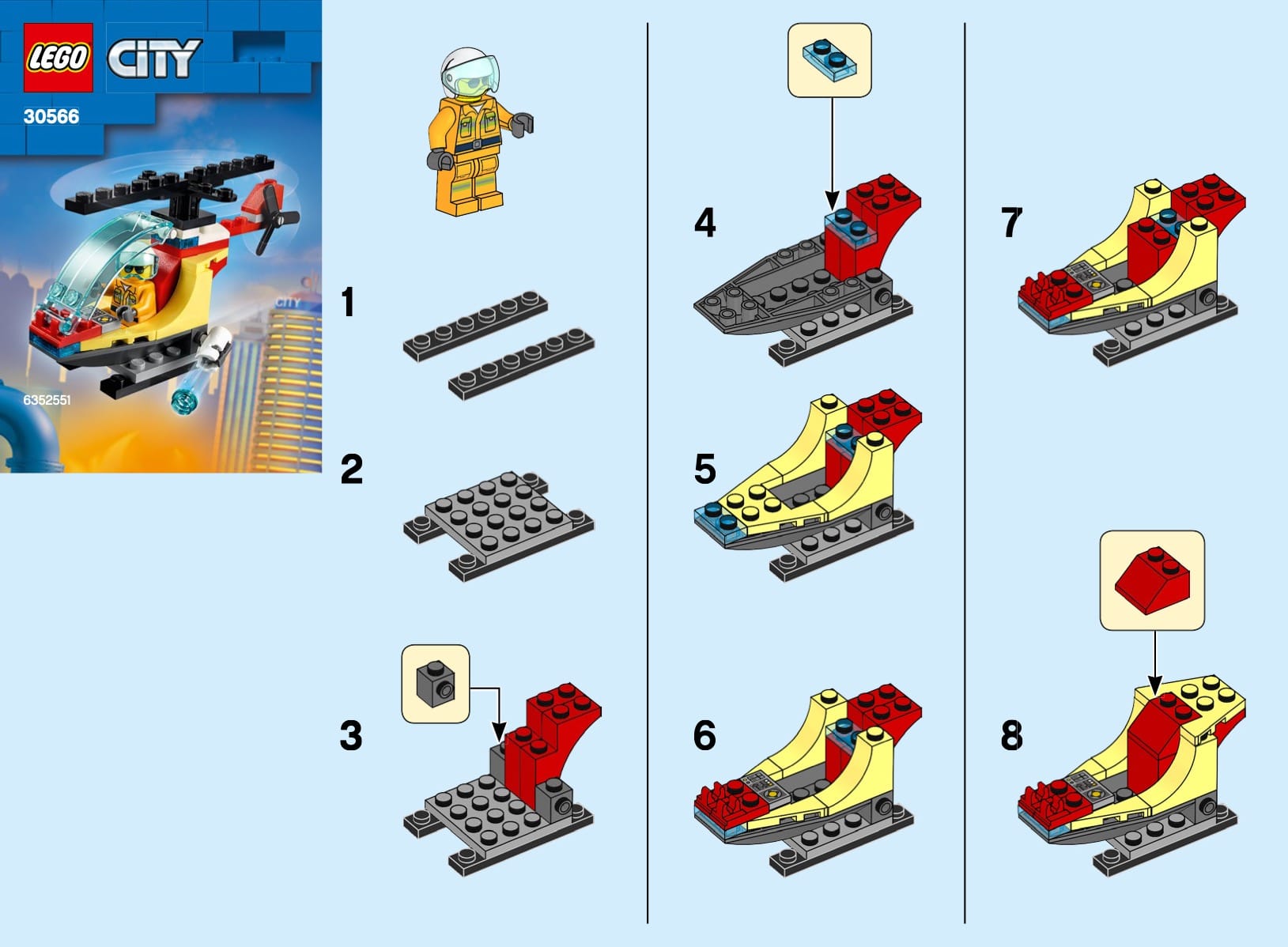

My son is nearly 4 years old, and he thoroughly enjoys building Lego with me. I've been experimenting with various levels of complexity, and it's been fascinating to observe how he processes the visual instructions before completing the task.

In the Lego visual work instructions shown above, you'll notice the absence of text. The sequence is straightforward, and whenever an image isn't immediately clear, an additional image is introduced to enhance understanding. Lego has perfected their visual instructions, thereby enriching the building experience of their products. As you develop your work instructions for manufacturing, aim to emulate Lego's approach, ensuring your visual instructions are so intuitive that every operator can effortlessly grasp the task at hand.

Retention Skyrockets with Images

Visuals are not merely embellishments; they serve as pivotal tools in enhancing memory retention and recall. When imagery accompanies instructions, it anchors concepts in the mind more firmly than text alone.

When instructions are visual, they capitalize on the brain's innate ability to recognize and remember images. This natural propensity for visual memory means operators can often execute tasks by recalling a sequence of images, rather than relying solely on written steps.

The ability of visuals to distill complex information into comprehensible segments cannot be overstated. Where engineering drawings demand interpretation and deep technical insight, well-crafted visual instructions provide the essence of the task at hand, enabling a broader audience to understand intricate procedures.

These visuals should accurately depict the actions the Operator will undertake. Ideally, they will incorporate the techniques or Tribal Knowledge necessary to accurately follow a sequence of steps.

Take Real World Pictures of the Process

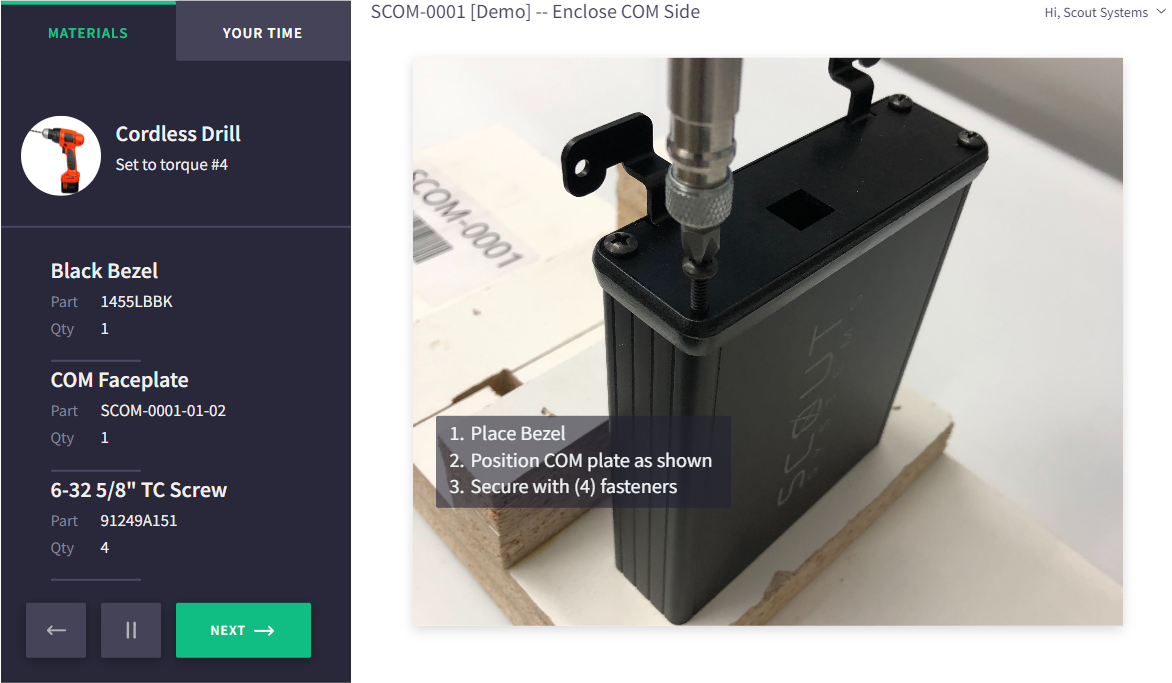

High-quality, real-life images provide an authentic representation of the assembly process, ensuring an accurate visualization.

- Select Appropriate Equipment: Use a high-resolution camera to capture clear and detailed images.

- Capture Multiple Angles: Photograph the process from various perspectives to give a comprehensive view.

- Ensure Proper Lighting: Illuminate the work area evenly to avoid shadows that can obscure details.

- Highlight Key Components: Focus on important parts and use indicators like arrows or circles to draw attention.

- Maintain Consistency: Keep a uniform style, background, and orientation for all pictures to ensure coherence.

These visuals allow Operators to relate instructions to the physical workspace with ease. Accurate, step-by-step visuals reduce cognitive load, ensuring that operators can follow procedures without ambiguity.

Utilizing Videos and PIP

Incorporating videos in work instructions enhances understanding and multiplies Tribal Knowledge by demonstrating the exact process of an advanced Operator.

- Outline the Procedure: Break down complex steps into short video segments for clarity.

- Film from Optimal Angles: Ensure each motion or action is visible and easily understood from the Operator's perspective.

- Use Picture-in-Picture (PIP) for Details: Employ PIP to make the video optional and accessible for those who desire greater assistance.

- Incorporate On-Screen Graphics: Add diagrams or text overlays to emphasize important information.

Implement Warnings

Warnings in visual work instructions are essential components that function as vital alerts, cautioning operators about potential hazards or emphasizing critical steps within a process. Advanced work instruction software, like Scout Systems', facilitates the integration of Safety and Defect warnings at the beginning of each process step. When properly implemented, these visual warnings enable a rapid and clear comprehension, significantly reducing the likelihood of accidents and errors in procedure.

Incorporating visual warnings directly supports a culture of safety and precision, ensuring that all operators are aware of the risks and required precautions before they commence a task. This preemptive approach to safety can dramatically lower the incidence of workplace injuries and enhance the overall quality of the manufacturing process.

Another widespread practice involves the use of icons within the instructions themselves, adopting the Picture-in-Picture (PIP) format. This method allows for the seamless integration of warning icons alongside the instructional content, ensuring that safety alerts are immediately visible in the context of the action being performed. By embedding these icons directly within the workflow, operators are constantly reminded of critical safety and quality information without disrupting the flow of their work.

The strategic placement of visual warnings and the use of universally recognized icons help in bridging communication gaps, making it easier for operators of diverse backgrounds and language proficiencies to understand and adhere to safety protocols. This not only enhances the effectiveness of the work instructions but also fosters a safer, more efficient working environment.

Involve Your Operators

The key to selecting the most effective visuals for your Work Instructions lies in soliciting and valuing the feedback of your Operators. Throughout my career in Manufacturing, I've encountered numerous instances where instructions were perplexingly complex. The purpose of creating visual instructions goes beyond merely ticking a box on a control plan; they should be regarded as a vital tool within your factory's operations. Empowering your Operators with the autonomy to provide feedback is essential in crafting the finest instructions possible. This collaborative approach not only aids in minimizing training time but also significantly reduces the chances of defects.

Engaging Operators in the development process ensures that the instructions are practical, understandable, and tailored to the actual experiences of those who use them daily. This hands-on feedback can highlight areas of confusion, suggest improvements, and identify the most effective visual aids, leading to a more intuitive and efficient workflow. By treating Operators as valuable contributors to the instruction design process, you foster a culture of continuous improvement and respect for the expertise of your workforce.

In essence, the success of visual work instructions hinges on their clarity, relevance, and the ease with which they can be followed. Achieving this level of effectiveness requires a deep understanding of the tasks at hand, an appreciation for the diversity of learning styles, and a commitment to iterative improvement based on direct feedback from the people who rely on these instructions the most. This approach not only enhances operational efficiency but also builds a stronger, more engaged team.

Ben Marsh

I've spent my career in Manufacturing, and can't stop trying to make things more efficient. At home, I am a master Lego builder with my son.

6 min read

6 min read