Jen Moore

I absolutely LOVE being outside. Being a soccer enthusiast and a dog mom, I spend much of my free time running with my pups or kicking a ball with my team.

The Six Barriers to Change in Manufacturing

Overcome change barriers in manufacturing: Address knowledge gaps, resistance, job security fears, and routine attachment to foster innovation and growth.

5 min read

5 min read

Jen Moore

WA, USA

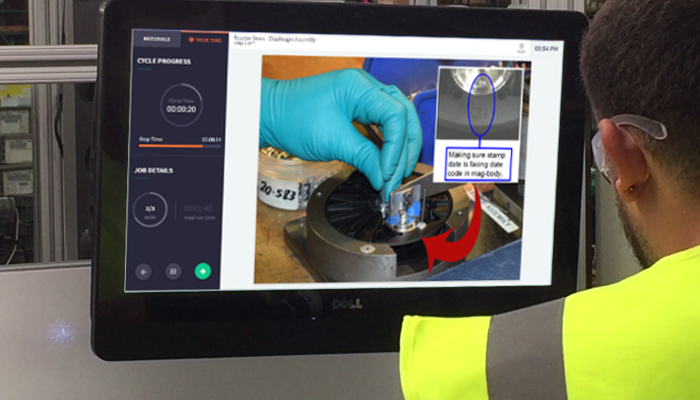

Reducing the Risk of Errors and Accidents

Boost factory safety with Scout Systems: Transition to digital work instructions to standardize processes, reduce errors, and enhance collaboration.

2 min read

2 min read

Jen Moore

WA, USA

Cost-Saving Benefits of Eliminating Paper

Go paperless with Scout Systems: Cut costs, boost efficiency, and ensure compliance. Start with our Accelerator Program for a seamless digital transition.

2 min read

2 min read

Jen Moore

WA, USA

Seize the Future of Manufacturing

Transform your manufacturing with Scout Systems' Accelerator Program: A 90-day plan for digital success with a 92% goal achievement rate. Start now!

1 min read

1 min read

Jen Moore

WA, USA

Dangers of Relying on Tribal Knowledge

Discover how digital work instructions mitigate the risks of tribal knowledge in manufacturing, ensuring quality control and scalability.

2 min read

2 min read

Jen Moore

WA, USA

The Power of Adaptability: Thriving in an Ever-Changing World

The relentless speed of technological advancements, shifting consumer demands, and intensifying global competition necessitate organizations to be more agile and adaptable than ever.

2 min read

2 min read

Jen Moore

WA, USA

Hidden Costs in Manufacturing: Human Error and Data Entry

The hidden costs of paper in manufacturing can add up quickly, leading to wasted resources, costly mistakes, and delays in production. By transitioning to a digital system, manufacturers can reduce the potential for human error and data entry mistakes, saving time and money in the long run.

2 min read

2 min read

Jen Moore

WA, USA

The Importance of Visual Learning: 3 Mistakes to Avoid

Maximize safety and efficiency by using visual aids, while steering clear of typical training errors.

2 min read

2 min read

Jen Moore

WA, USA